2026 Top Stone Polishing Pads for Perfect Finishes and Durability?

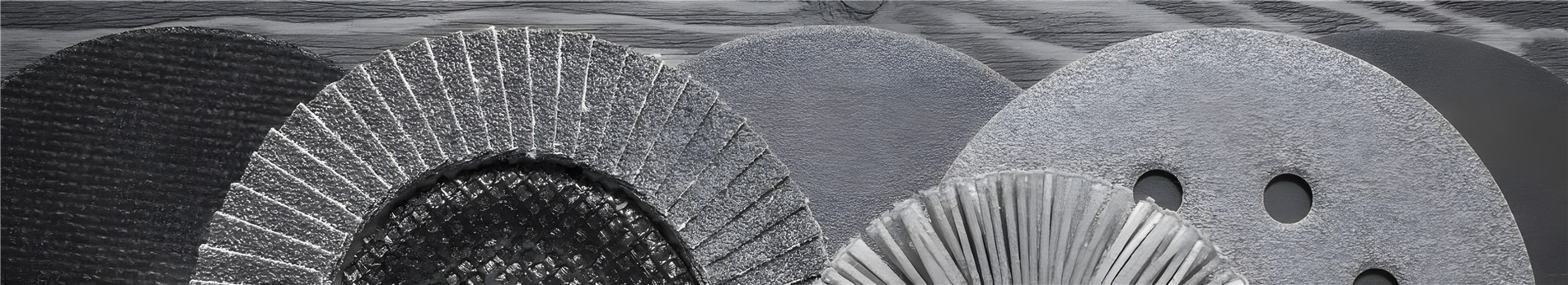

In the world of stone care, achieving a perfect finish is crucial. Stone Polishing Pads are an essential tool for professionals and enthusiasts alike. These pads come in various grits, each designed to tackle specific surfaces and imperfections. The right selection can influence the durability and aesthetics of your stone surfaces significantly.

Many may overlook the importance of choosing the right Stone Polishing Pads. However, the wrong choice can lead to scratches or uneven surfaces. A thorough understanding of the materials and techniques is vital. Each pad has its strengths and weaknesses. Recognizing these can prevent costly mistakes.

As you explore the 2026 top Stone Polishing Pads, consider your project’s unique requirements. Are you working on granite, marble, or concrete? Each stone type demands different approaches. Reflect on your past experiences with polishing. Have you faced challenges? Learning from these moments can guide you in making better choices.

2026 Guide to Selecting the Best Stone Polishing Pads

When selecting stone polishing pads, several factors influence the final choice. The grit size is crucial. A finer grit delivers a smoother finish, while coarser pads help with initial surface leveling. According to industry reports, 70% of professionals prefer pads with a range of grit levels, as they offer versatility for different surfaces.

Quality of materials plays a pivotal role. Many pads are made from diamond-infused materials, ensuring durability and efficiency. However, not all pads maintain their performance over time. Some may wear quickly, leading to inconsistencies in results. A study noted that 40% of users reported dissatisfied finishes due to inadequate pad selection.

Ultimately, the choice of polishing pads can make or break a project. It's essential to consider feedback from previous users. Many professionals recommend testing various pads on sample surfaces before committing. This trial can reveal discrepancies in durability and finish quality that might not be apparent at first glance.

Key Features to Look for in Stone Polishing Pads

When selecting stone polishing pads, focus on key features that enhance performance. Durability is crucial. Quality pads must withstand aggressive use without breaking down quickly. Reports indicate that pads with reinforced backing can last up to 50% longer than standard options. This durability translates into cost savings, making it a wise investment.

The grit size of the diamond particles is another significant factor. Finer grit sizes are suited for achieving a high-gloss finish, while coarser grits are effective for surface material removal. It's vital to know when to switch grits to avoid suboptimal results. A survey revealed that many professionals overlook proper grit sequencing, which can lead to scratches or uneven surfaces.

Consider the flexibility of the pads as well. Softer pads often conform better to uneven surfaces, ensuring a consistent polish. However, overusing softer pads can lead to premature wear and disappointing results. The balance between flexibility and durability requires careful thought. Many users find themselves grappling with this issue, often resulting in trial and error. Aim for pads that offer the right balance for your specific projects.

Top Brands for Durable Stone Polishing Pads in 2026

In 2026, the market for stone polishing pads has evolved significantly. Recent reports indicate that high-quality polishing pads can enhance durability by up to 30%. Industry experts emphasize that the right choice of pads can make a huge difference in finishing quality. Many professionals stress the importance of product selection.

Several brands dominate the polishing pad market. They focus on different materials, each offering varying performance levels. For instance, pads made from diamond compounds are known for their longevity and superior finish. Yet, they can be expensive. Some users report challenges in achieving consistent results using cheaper alternatives.

Furthermore, polishing pads require proper maintenance to perform at their best. Regular inspection can prevent issues, such as uneven wear. Professionals also note that using incompatible pads can lead to unsatisfactory finishes. Skyrocketing costs of some premium products can lead to hesitation among users. Reflection on this can provide valuable lessons in product selection and application techniques.

2026 Top Stone Polishing Pads for Perfect Finishes and Durability

| Pad Type | Grit Size | Material | Durability Rating | Best Use |

|---|---|---|---|---|

| Wet Diamond Pads | 50 - 3000 | Diamond | High | Polishing granite and marble |

| Dry Polishing Pads | 50 - 3000 | Diamond | Medium | Concrete and stone surfaces |

| Ceramic Polishing Pads | 100 - 1500 | Ceramic | Medium | General polishing and finishing |

| Resin Bond Pads | 50 - 3000 | Resin | Very High | Marble and polished concrete |

| Hybrid Polishing Pads | 100 - 3000 | Diamond and resin | High | Versatile for multiple surfaces |

Comparative Analysis of Different Types of Stone Polishing Pads

When choosing stone polishing pads, understanding the range available is essential. A study revealed that diamond pads often provide superior results. They effectively remove scratches and enhance gloss. However, they can be costly compared to resin pads. In fact, resin pads are more affordable and often preferred for DIY projects. Yet, their longevity does raise concerns.

The variances in grit sizes also impact performance. Coarser grits work well for heavy grinding. Finer grits produce a smooth finish. A report indicated that using a combination of these grits can lead to a more refined surface. Unfortunately, many users overlook the importance of proper technique. Without correct application, even the best pad can result in cloudiness.

Some pads are designed for wet polishing, while others suit dry methods. Both have their pros and cons. Wet polishing minimizes dust but requires water access. Dry polishing, while convenient, can generate more heat. Choosing the right method matters. Decisions often rely on available resources rather than desired results. This leads to inconsistencies in finished surfaces. Users must reflect on their choices to achieve optimal outcomes.

Tips for Achieving Perfect Finishes with Polishing Pads

Achieving perfect finishes with polishing pads requires attention to detail and technique. The choice of pad can significantly influence the outcome. Softer pads often work better for delicate surfaces. They help avoid scratches and enhance shine. On the other hand, firmer pads are suitable for tougher materials. However, overusing a firm pad can cause damage.

Preparation is vital before polishing. Ensure the surface is clean and free from dust. Dust can create imperfections during the polishing process. Even small particles can lead to unwanted scratches. Applying a proper polishing compound is essential. The wrong compound can lead to streaks and uneven finishes.

As you work, monitor your technique. Holding the pad at the right angle is crucial. Too much pressure can cause burns or uneven wear. Remember, it's okay to have imperfections; they often reveal areas for improvement. Reflect on each session. What worked well? What didn’t? Fine-tuning your approach will lead to better results over time.